CFD simulations of the melting furnace and development of a digital twin at ASAS

RETROFEED is a European funded project that aims to boost the use of increasingly variable, bio-based and circular feedstock in process industries by retrofitting core equipment and implementing an advanced monitoring and control system. One of the Resource and Energy Intensive Industries (REII) sectors is aluminum. For that industry the objectives are to increase the amount of scrap aluminium in the melting furnace to save resources and energy and decrease CO2emission.

The retrofitting solutions in this demo site are focused on the design of a new burner head, oxygen injector system and development of Digital Twin (DT) which will be integrated in the Decision Support System (DSS), allowing the user for the process optimisation. In fact, the activities described in the last submitted deliverable have been:

- Numerical investigation of current performance of ASAS melting furnace.

- Simulate furnace operation at different operational conditions.

- Test of different burner heads to optimise their design.

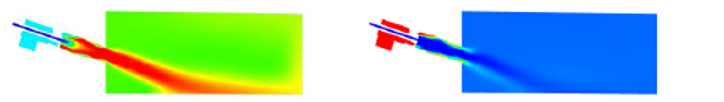

Figure 1. Temperature and oxygen profile for one burner

- CFD simulations of the new oxygen injector system.

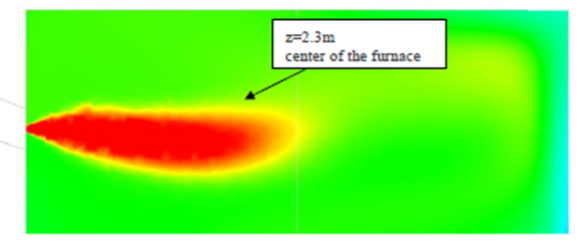

Figure 2. Contours of mole fraction of O2

- Development of Digital Twin of the process with selected burner head.

- Experimental investigation and model development of dross formation which can be applied as part of DT.

Figure 3. Apparatus for dross formation tests

Besides, all above aims must simultaneously fulfil the limits and constrains such as limits of NOx emissions, uniform oxygen concentration within the furnace, elimination of uncomplete combustion and hot spots, increase the scraps share in feedstock without decreasing of Al quality and improve overall process efficiency.

Therefore, because of this deliverable, a Digital Twin has been provided by IEN that allows quick testing of different operational scenarios and virtual prototyping of the new solutions. This DT of the melting furnace will be integrated in the Decision Support System (DSS) of the project in the next months.