RETROFEED Decision Support System (DSS) release

The Retrofeed Project objective is the retrofitting of 6 different industrial processes to reduce both their environmental impact and reduce the dependency on certain raw materials introducing innovative circular economy concept in the value chain.

The 6 plants focus of the project are being retrofitted with the development of new hardware technologies (e.g. new material injectors, new sensors for advanced monitoring etc…) and the introduction of modern software application which could help, in the long term, optimize the process even further, reducing costs, the use of impactful raw materials and waste.

For this reason, Optit, the main digital partner in the project, closely worked with the industrial partners and the research centers to develop what is called a Decision Support System (DSS) specifically designed to monitor, analyze and simulate the core processes exploiting a series of advanced digital models tailor made for each project use case. Modelling approaches span from CFD-Reduced order models (ROM), machine learning, optimization and first order models of side processes in order to mimic, as closely as possible, the industrial process introducing also a first level of optimization intelligence.

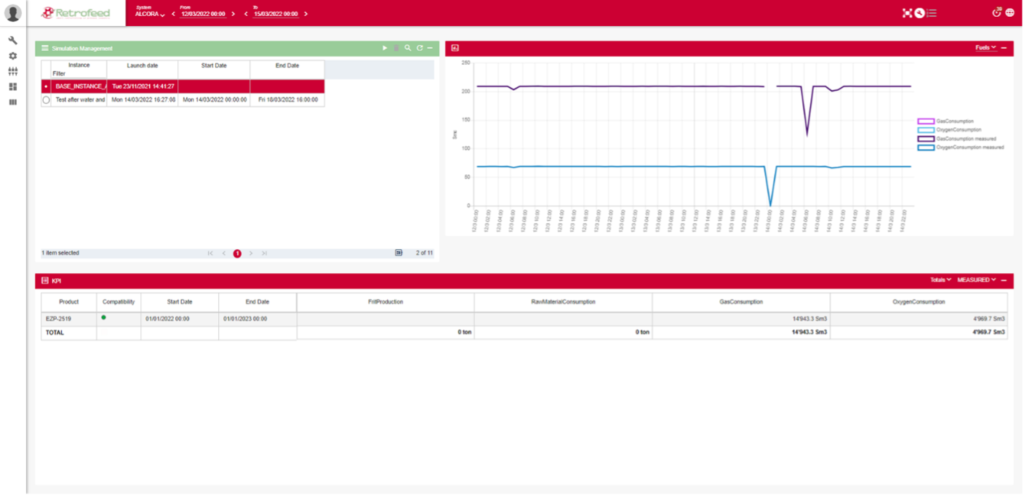

The DSS (shown in the pictures) was designed as a web app and developed with two different approaches: one for batch type processes (e.g., Steel, Aluminum) and the other for continuous process (e.g., Ceramic, Cement) with the possibility to: simulate the process using the models embedded and monitor the current processes thanks to a series of “connectors”, specifically developed for the project, to gather data from the various plant systems.

The main dashboard is divided in three areas: an area where field data and simulation are managed, a KPI table with a summary of the core process activities and a larger area on the right side where a series of charts are placed to visualize trends, profiles or any time-dependent data.

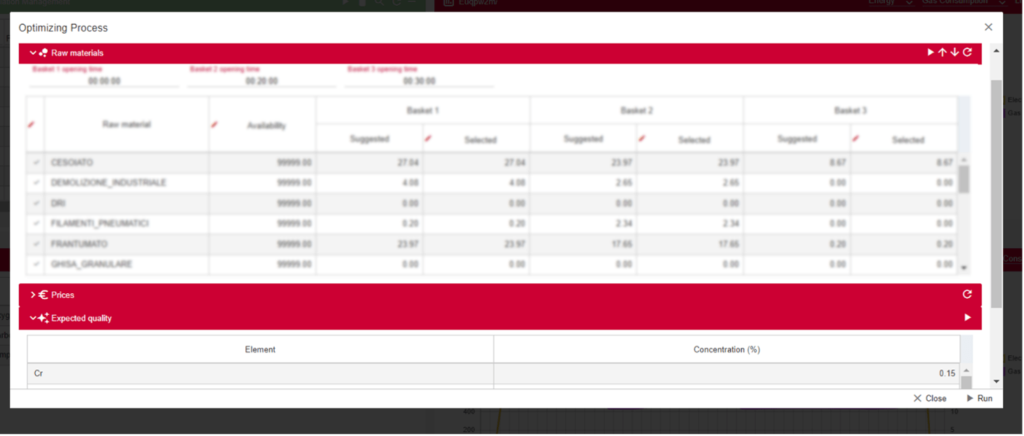

From the simulation management table is possible to launch a pop-up window which is used for the simulation/optimization process. Each use cases, having different models, needed specific interfaces in order to handle the multiple variables, parameters and constraints so Optit designed and developed custom elements to simplify the handling and the launch of these models even for non-expert users.

The first Beta of the Retrofeed-DSS was already released to Ferriere Nord and Torrecid which have already started the first tests. In the next weeks, the DSS will be released to the other partners officially ending the development phase starting a phase focused on testing and refining the tool and the models.

Figure 1: Main Simulation dashboard

Figure 2: Model Launch interface

Until now, the work in FENO demo site has been focused to design the new burner, tested by mean of CFD simulations and compared to a CFD simulation of the existing burner. By comparing the velocity and temperature field, it has been seen the new burner has the same performance of the existing burner. Furthermore, burning plastic has the same effect of burning methane due to the high heating value of plastics. Thus, it has been demonstrated that plastic burner can replace methane burner and, therefore, partners are now manufacturing the innovative burner to be installed in FENO plant. For SILCOTUB demo site it has been designed a system to partially replace coal, lime and scrap for injecting carbon substitutes and co-product/residues particles from the steel industry (i.e., residues containing CaO, C, FeO, Mg and Al2O3) and possibly with similar residues from other industrial sectors. Finally, all these activities have been complemented with an exhaustive characterisation of the alternative materials to be burnt or blown in both demo sites to have information about chemical analysis, dimensional analysis and behaviour during heating.

Figure 3: Production Plan Continuous Process